What is DMLS?

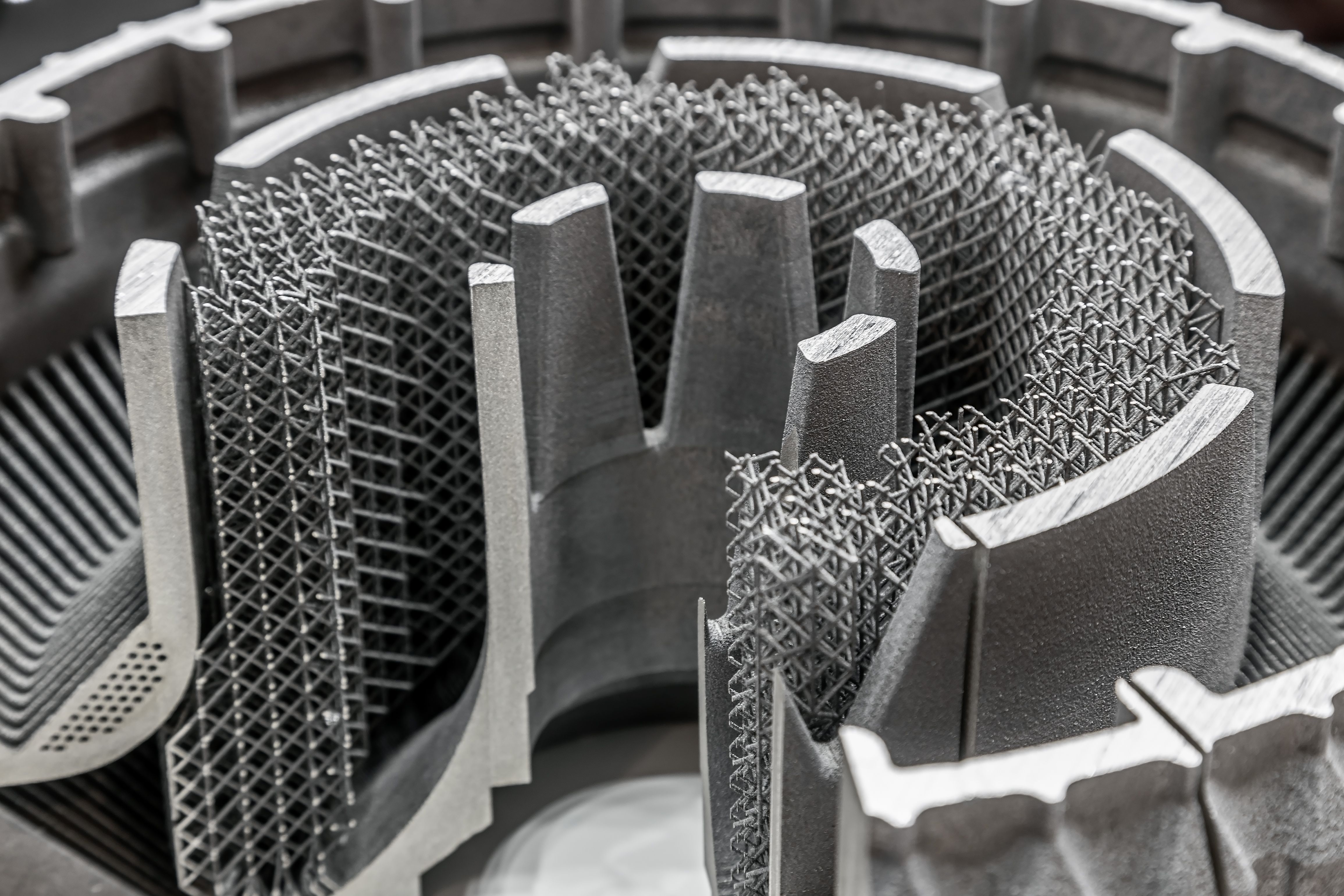

Direct Metal Laser Sintering (DMLS) is an advanced 3D printing technology that transforms metal powder into solid, fully functional parts. Using a high-powered laser, DMLS fuses the powder layer by layer, building components with exceptional precision and strength. This process allows for the creation of complex geometries that are often impossible to achieve with traditional manufacturing methods.

Why Choose DMLS?

DMLS offers unique advantages, making it a preferred choice for engineers and manufacturers:

- High Precision: Delivers tight tolerances and intricate details, perfect for complex designs.

- Versatility: Ideal for rapid prototyping, low-volume production, and custom parts that traditional methods can’t produce.

- Speed: Reduces lead times, enabling faster design iterations and product development.

- Durability: Creates fully dense metal parts with mechanical properties comparable to those made through machining or casting.

Materials Available

Wellan provides a variety of high-quality metal options for DMLS, tailored to diverse project requirements:

- Stainless Steel: Corrosion-resistant and durable, great for functional prototypes and end-use parts.

- Aluminum: Lightweight and strong, widely used in aerospace and automotive industries.

- Titanium: Offers an excellent strength-to-weight ratio, ideal for medical implants and high-performance components.

- Inconel: Heat- and corrosion-resistant, suited for extreme conditions in aerospace and energy applications.

For more details on available materials, check out Wellan’s 3D Printing Materials page.

Applications of DMLS

DMLS is widely used across industries due to its precision and flexibility. Common applications include:

- Rapid Prototyping: Quickly produce accurate metal prototypes for design validation.

- Functional Testing: Create parts for mechanical, thermal, or performance testing.

- Custom Manufacturing: Perfect for low-volume production of specialized components in fields like aerospace, automotive, and medical.

- Complex Designs: Enables the production of intricate structures, such as lattices or internal channels, that traditional methods can’t replicate.

Wellan’s Expertise in DMLS

Wellan stands out as a trusted partner for DMLS manufacturing. With cutting-edge equipment and a team of experienced engineers, we ensure every part meets your exact specifications. From material selection and design optimization to precision printing and post-processing, Wellan delivers reliable, high-quality metal components for your projects.