What is Post-Processing and Inspection?

Post-processing and inspection are essential steps in the manufacturing process, particularly for additive manufacturing. Post-processing involves refining a part after it’s been produced, which can include removing support structures, cleaning, sanding, painting, or applying coatings to enhance its appearance and functionality. Inspection ensures the part meets quality standards through checks like dimensional accuracy, surface finish, and functional testing.

Why Choose Post-Processing and Inspection?

These services are crucial for delivering high-quality, reliable products:

- Enhanced Quality: Post-processing improves the part’s durability and aesthetics, while inspection catches defects early.

- Precision and Consistency: Detailed inspections ensure every part meets exact specifications.

- Efficiency: Streamlined processes reduce production time and waste, keeping projects on track.

Services Offered by Wellan

Wellan provides a range of post-processing and inspection services tailored to your project’s needs:

- Coatings: Protective finishes like powder coating or plating for durability.

- Paints: Custom colors and finishes for branding and performance.

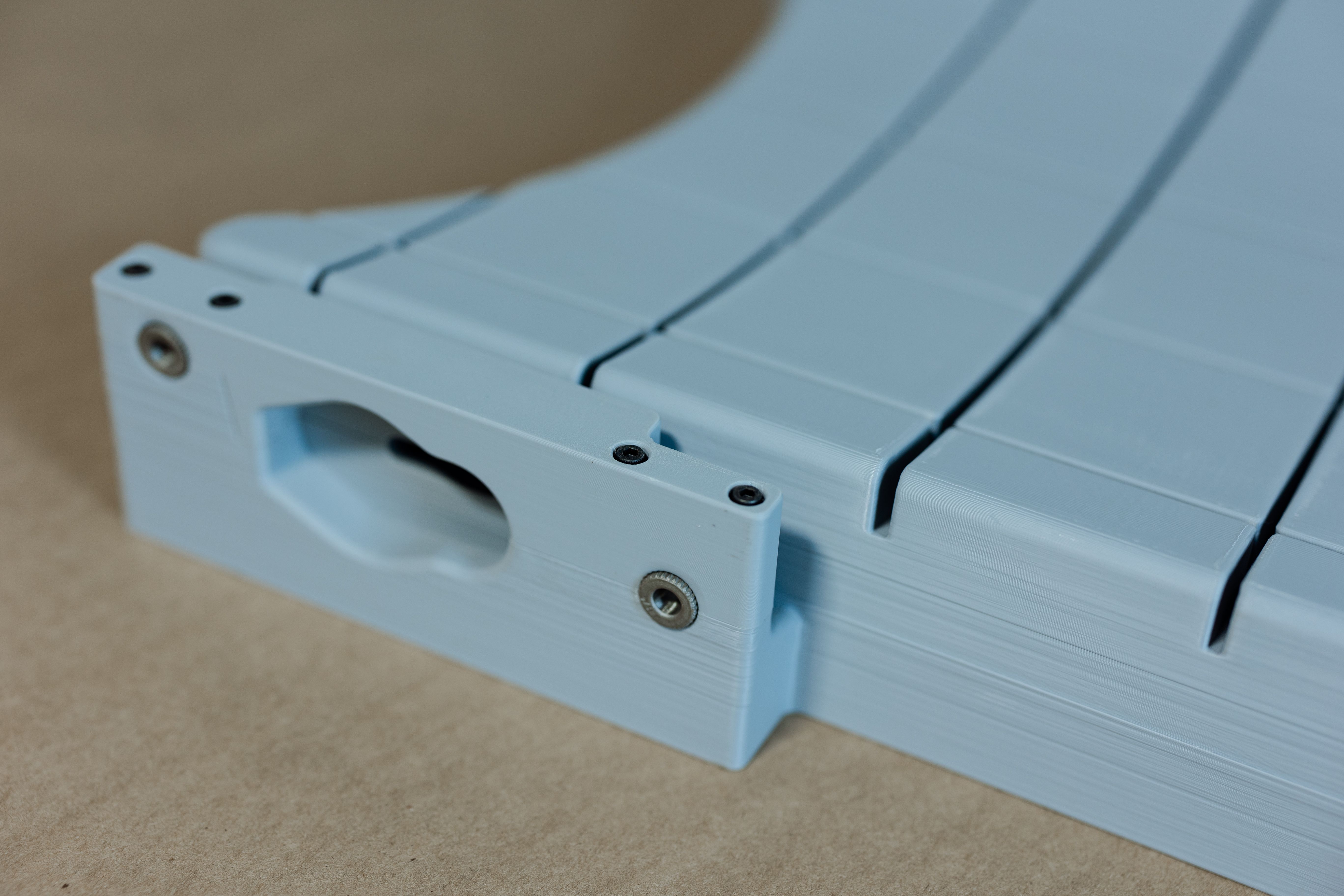

- Surfacing: Techniques like sanding or polishing for desired textures.

- Inserts: Threaded inserts or bushings for added strength and ease of assembly.

- Assemblies: Integration of parts into complete, tested systems.

For inspection, Wellan offers comprehensive quality assurance, with specific methods available upon inquiry. Contact us for details.

Wellan’s Post-Processing and Inspection Service

Wellan’s team leverages advanced tools and techniques to deliver parts that meet the highest standards. With a focus on precision, efficiency, and customer satisfaction, we ensure your parts are refined, validated, and ready for their intended use.