What is Injection Molding and Why Choose It?

Injection molding is a manufacturing process where molten material, in our case thermoplastics, is injected into a mold to create parts with high precision and repeatability. It’s perfect for producing large volumes of identical components with complex shapes.

Why choose injection molding?

- Cost-effective: Efficient for high-volume production, lowering per-part costs.

- High precision: Delivers tight tolerances and consistent quality for intricate parts.

- Versatile materials: Supports a wide range of thermoplastics for various needs.

- Complex designs: Enables production of detailed shapes with excellent finishes.

Materials Available for Injection Molding

At Wellan, we exclusively use thermoplastics for injection molding, offering a variety tailored to your project’s needs:

- ABS: Strong, durable, and impact-resistant, great for automotive parts and consumer goods.

- Polycarbonate: Highly transparent, heat-resistant, and tough, ideal for electronics and medical devices.

- Nylon: Offers excellent wear resistance and low friction, perfect for gears and industrial components.

- Polypropylene: Lightweight, flexible, and chemically resistant, suited for packaging and household items.

For a full list of our thermoplastic options, check out our Injection Molding Materials page.

Applications of Injection Molding

Our thermoplastic injection molding serves numerous industries, such as:

- Automotive: Interior/exterior parts and under-the-hood components.

- Consumer goods: Toys, household items, and packaging.

- Medical devices: Precise, sterile healthcare components.

- Electronics: Housings, connectors, and small intricate parts.

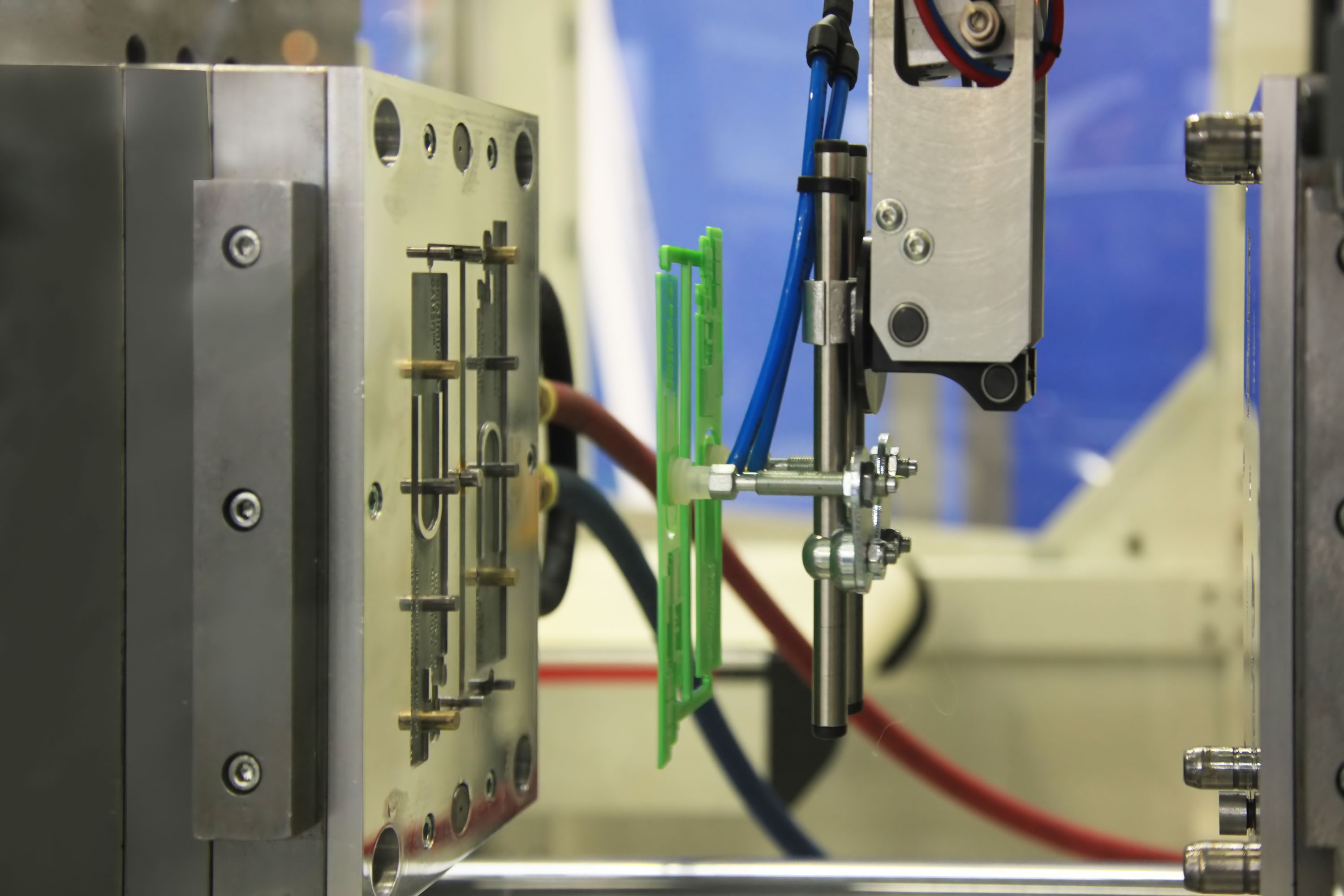

Wellan’s Injection Molding Service

Wellan’s injection molding service leverages cutting-edge technology and skilled expertise, focusing solely on thermoplastics. We provide end-to-end support—from design optimization to production—ensuring top-quality parts, efficient manufacturing, and on-time delivery for your success.