3D Printing Materials Guide

At Wellan, we understand that selecting the right 3D printing material is crucial for your project’s success. Our comprehensive range of materials is designed to meet various needs, from rapid prototyping to high-performance end-use parts. Use this guide to find the right material for your application.

Quick Material Selection Guide

Not sure where to start? Use this guide to narrow down your choices:

- What is your primary goal?

- Prototyping or concept modeling: See General Performance materials.

- Functional testing or low-volume production: See Engineering Performance materials.

- High-performance or end-use parts: See High Performance or Hyper Plastics.

- What printing technology are you using?

- FDM: Filaments

- SLA/MSLA: Resins

- SLS/MJF: Plastic Powders

- DMLS: Metal Powders

- Do you have specific requirements (e.g., heat resistance, flexibility)?

- Yes: Look for materials with those properties below.

- No: Start with General or Engineering Performance materials.

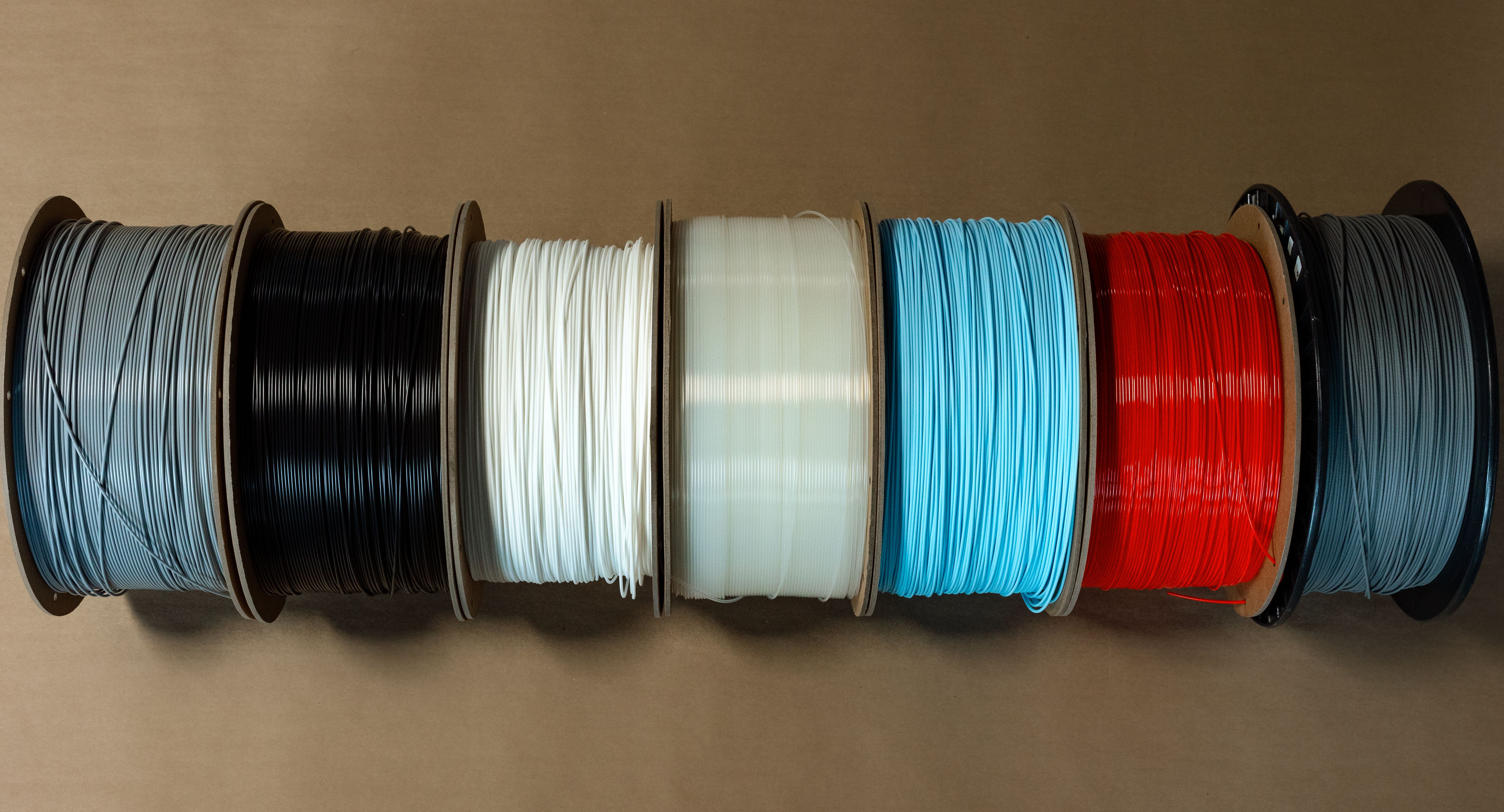

Filaments

General Performance

- Description: Standard materials for everyday printing, suitable for basic models and initial designs.

- Key Properties: Affordable, easy to print, good for beginners.

- Applications: Concept models, prototypes for displays, system mockups.

- Common Materials: PLA, ABS, similar plastics.

Engineering Performance

- Description: Enhanced strength and durability, ideal for demanding projects.

- Key Properties: Better mechanical properties, suitable for functional parts.

- Applications: Functional components, durable housings, flexible system parts.

- Common Materials: PETG, Nylon, comparable materials.

High Performance

- Description: Superior resistance for challenging environments.

- Key Properties: Heat resistance, chemical resistance, high strength.

- Applications: Heat-resistant parts, tough casings, industrial components.

- Common Materials: PPU, PPS, high-end plastics.

Hyper Plastics

- Description: Specialty materials for advanced or custom applications.

- Key Properties: Unique properties like biocompatibility, conductivity.

- Applications: Specialized covers, conductive elements, unique enhancements.

- Common Materials: PEEK, PEKK, PEI, advanced plastics.

Resins

General Performance

- Description: Basic resins for standard printing, perfect for detailed models and initial casts.

- Key Properties: High detail, smooth surface finish.

- Applications: Prototype casings, decorative parts, system visualization models.

- Common Materials: Standard, ABS-Like resins.

Engineering Performance

- Description: Built for strength and detail, suited for durability and precision.

- Key Properties: Tougher, more impact-resistant.

- Applications: Functional fittings, durable components, industrial mockups.

- Common Materials: Tough, Nylon-Like resins

High Performance

- Description: Top-tier resins for demanding applications, offering resilience and fine detail.

- Key Properties: Heat tolerance, high strength.

- Applications: Heat-tolerant parts, strong enclosures, heavy-duty components.

- Common Materials: Somos & Accura brand resins.

Plastic Powders

- Description: Used to create detailed, flexible parts with good mechanical properties.

- Key Properties: Good for complex geometries, functional parts.

- Applications: Complex components, flexible connectors, prototype structural elements.

- Common Materials: Nylon-based, TPU, other plastic blends.

Metal Powders

- Description: For producing strong, precise metal parts.

- Key Properties: High strength, heat resistance, suitable for end-use parts.

- Applications: Durable fittings, reinforced bases, industrial assemblies.

- Common Materials: Stainless steel, aluminum, titanium, metal blends.