What is FDM and Why Choose It?

Fused Deposition Modeling (FDM) is a 3D printing technology that builds parts by depositing molten thermoplastic material layer by layer. It’s a go-to solution for cost-effective, fast, and versatile manufacturing, perfect for both prototyping and production.

Why choose FDM?

- Cost-effective: Affordable materials and production keep your budget in check.

- Fast turnaround: Quick printing speeds get your parts ready sooner.

- Versatile: Works for everything from simple prototypes to functional components.

Materials Available for FDM

Wellan offers a diverse range of FDM materials to suit various project requirements:

- General Purpose Plastics: Materials like PLA are ideal for prototypes, concept models, and visual aids due to their ease of use and affordability.

- Engineering Plastics: Materials such as ABS, PETG, nylon, and polycarbonate (PC) provide enhanced strength, heat resistance, and durability, making them suitable for functional prototypes and end-use parts.

- High-Performance Plastics: For demanding applications, materials like PPS (Polyphenylene Sulfide) and PPU (Polyphenylsulfone) offer superior mechanical properties, chemical resistance, and thermal stability.

- Hyper Plastics: Specialized materials like PEKK (Polyetherketoneketone), PEEK (Polyetheretherketone), and PEI (Polyetherimide) provide exceptional performance in extreme conditions, ideal for aerospace and medical applications.

For a comprehensive overview of our material offerings and their properties, visit our 3D Printing Materials page.

Applications of FDM

FDM’s versatility makes it a valuable tool across various industries. Key applications include:

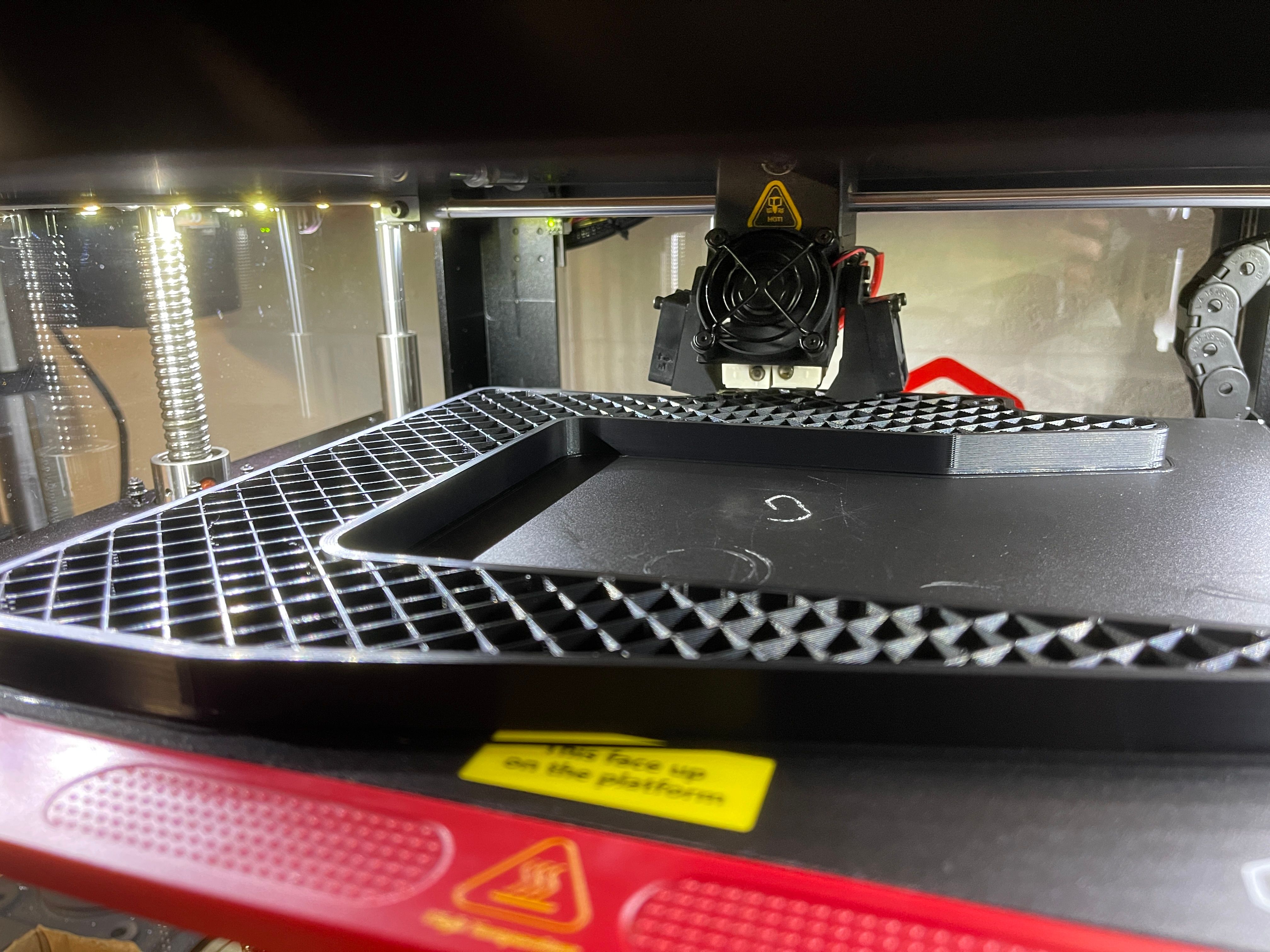

- Rapid Prototyping: FDM’s speed and cost-effectiveness enable quick iteration and refinement of prototypes.

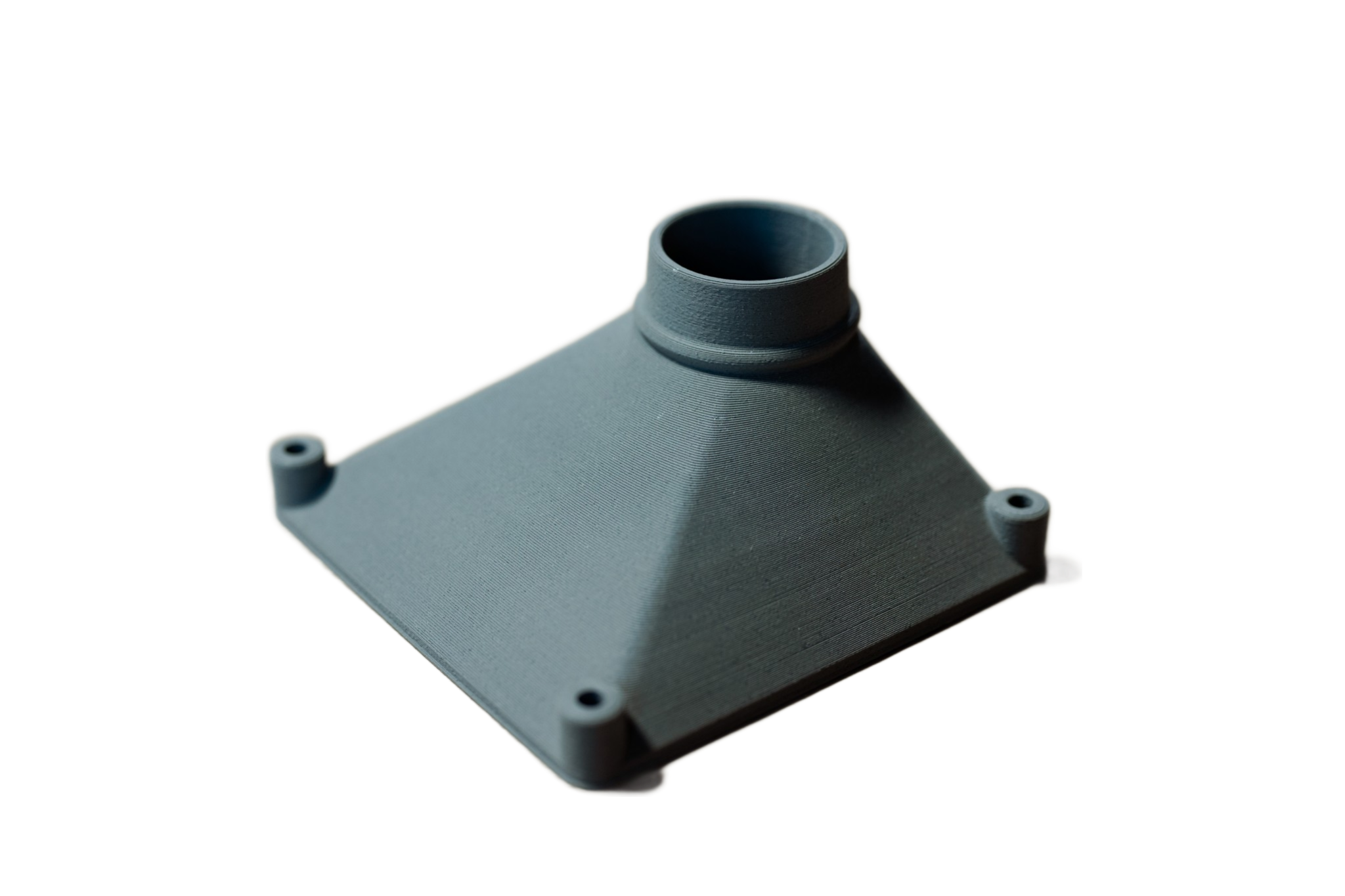

- Jigs, Fixtures, and Production Tools: Custom-designed jigs, fixtures, and tools like trays and holders streamline workflows and improve efficiency in manufacturing processes.

- Industrial Components: FDM is used to create custom hardware components for commercial hardware, industrial equipment, and specialized machinery.

- Consumer Components: FDM supports the production of customized consumer goods, from personalized items to functional housings.

Wellan’s FDM Service

Wellan’s FDM service delivers reliable, high-performance parts through material expertise, design optimization, and rigorous quality control. Our team tailors material selection and print parameters to your project’s needs, ensuring strength, durability, and precision with advanced calibration and thorough inspections.