What is SLA and Why Choose It?

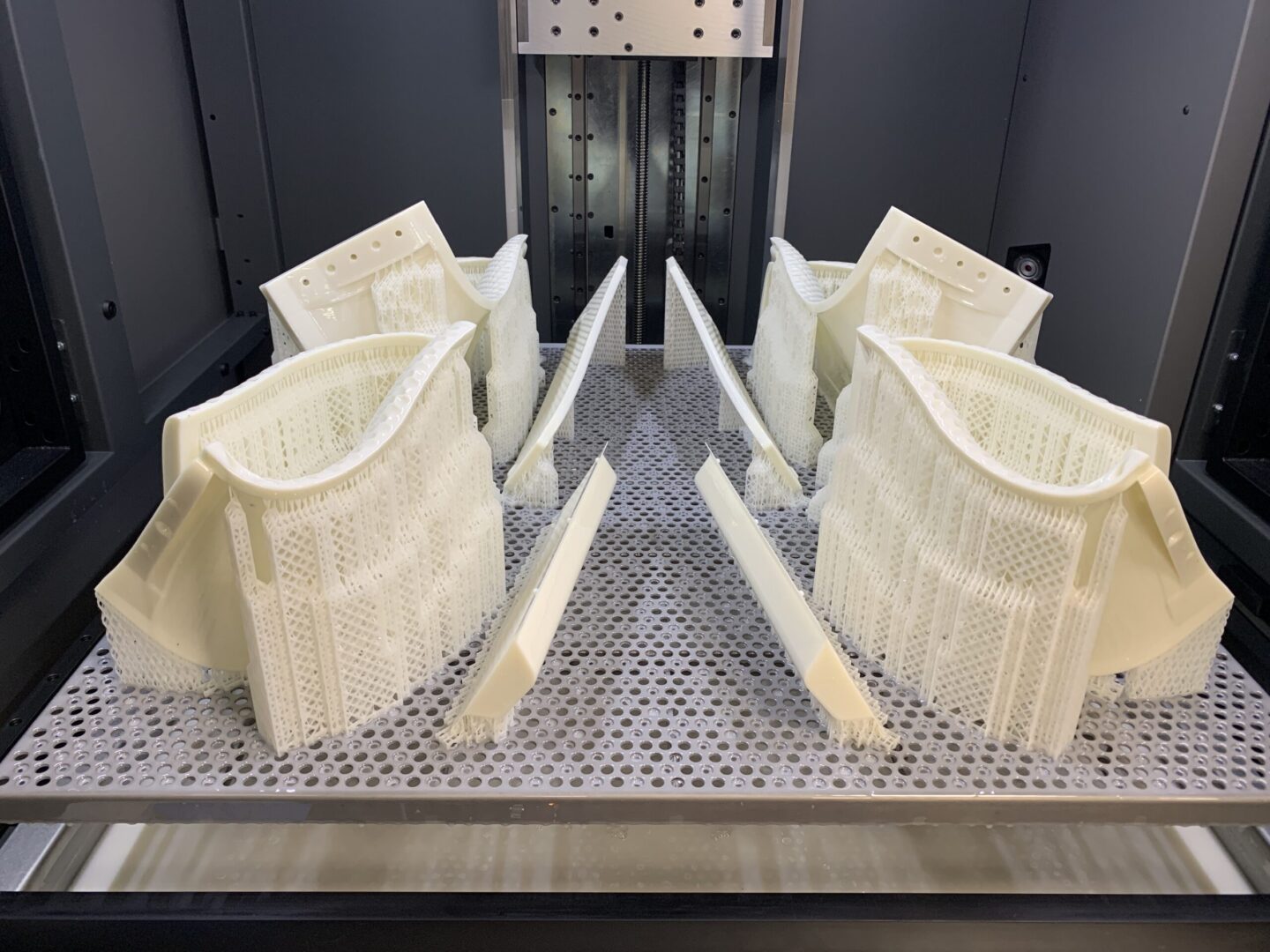

Stereolithography (SLA) is a cutting-edge 3D printing technology that uses ultraviolet (UV) light to transform liquid photopolymer resin into solid parts, layer by layer. Renowned for its precision and versatility, SLA is perfect for producing highly detailed prototypes and functional components with smooth, professional-grade surface finishes.

Why choose SLA?

- High Accuracy: Achieve exceptional detail and tight tolerances, ideal for intricate and complex designs.

- Smooth Finishes: Parts rival the quality of injection-molded components, offering a polished appearance.

- Fast Turnaround: Speed up design iterations and accelerate your product development timeline.

Materials Available for SLA

Wellan provides a variety of SLA materials tailored to your project’s specific requirements:

- General Purpose Resins: Great for visual prototypes and concept models.

- Engineering Resins: Offer improved strength, durability, and heat resistance for functional testing.

- High-Performance Resins: Built for demanding applications needing excellent mechanical and chemical properties.

- Specialty Resins: Options like clear resins for transparency or flexible resins for unique uses.

Explore our full range of SLA materials on our 3D Printing Materials page.

Applications of SLA

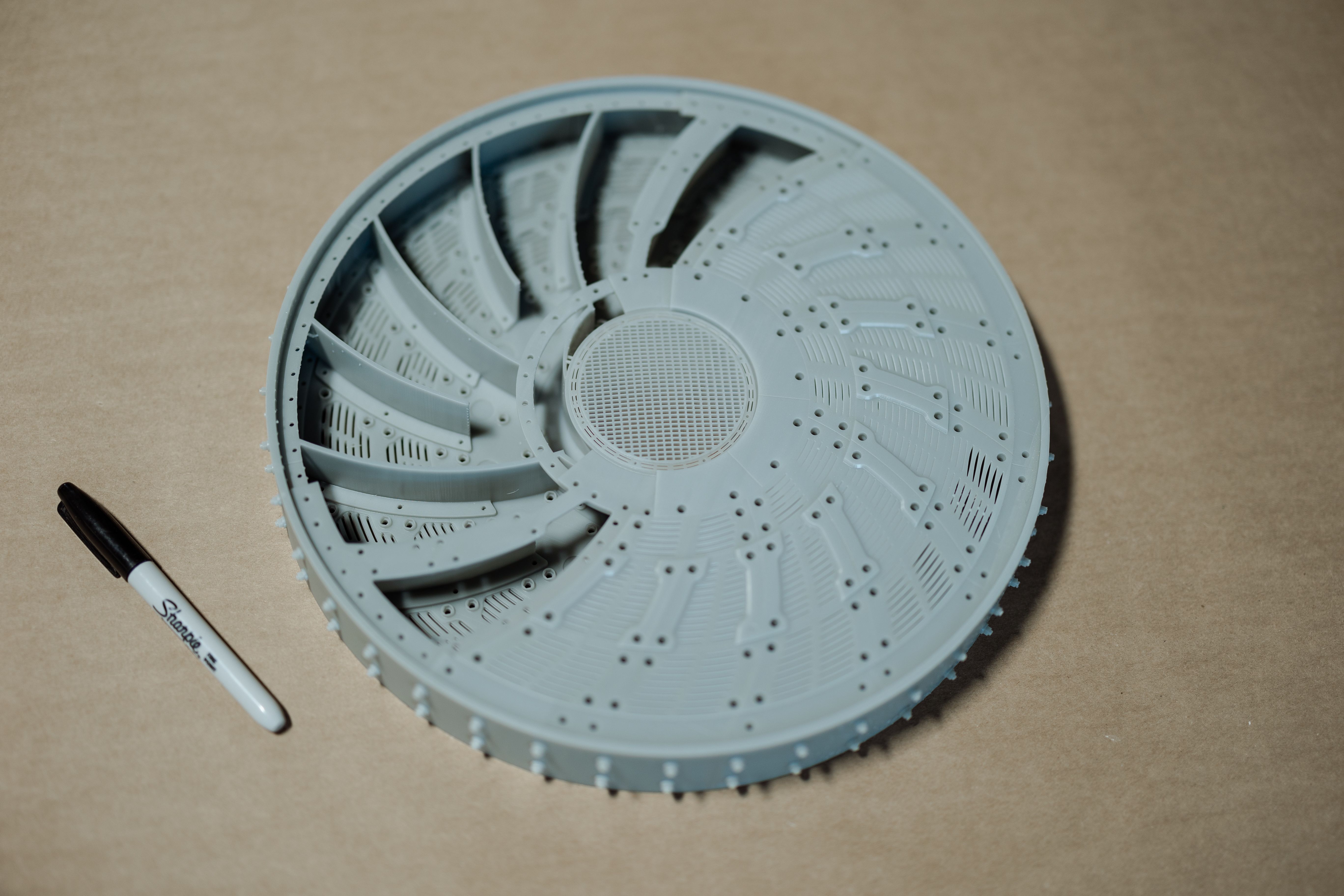

SLA’s precision and adaptability make it a go-to solution for numerous industries. Key uses include:

- Rapid Prototyping: Quickly create accurate prototypes to refine designs and validate concepts.

- Functional Testing: Produce parts for mechanical, thermal, or chemical performance evaluations.

- Custom Components: Perfect for low-volume production of specialized parts, such as those used in medical devices or aerospace.

- Visual Models: Ideal for tradeshow displays, client presentations, or design reviews with its sleek finishes.

Wellan’s SLA Service

At Wellan, we elevate SLA manufacturing with advanced technology and expert craftsmanship. Our team optimizes every project through precise print control, carefully selected materials, and thorough quality assurance. We focus on design optimization to ensure parts are strong, durable, and perfectly suited to their purpose.